Unmistakably Belgian, the Merckx EMX 3 is an endurance-type, carbon road frame designed to battle the elements and harsh roads of northern Europe. However, brutal accidents can happen and damage even the most robust of carbon fiber frames. This specific Merckx arrived for repair after our customer toppled over and damaged the toptube. Fortunately, damaged toptubes are our bread and butter, so we were absolutely confident we would be able to save this frame as well.

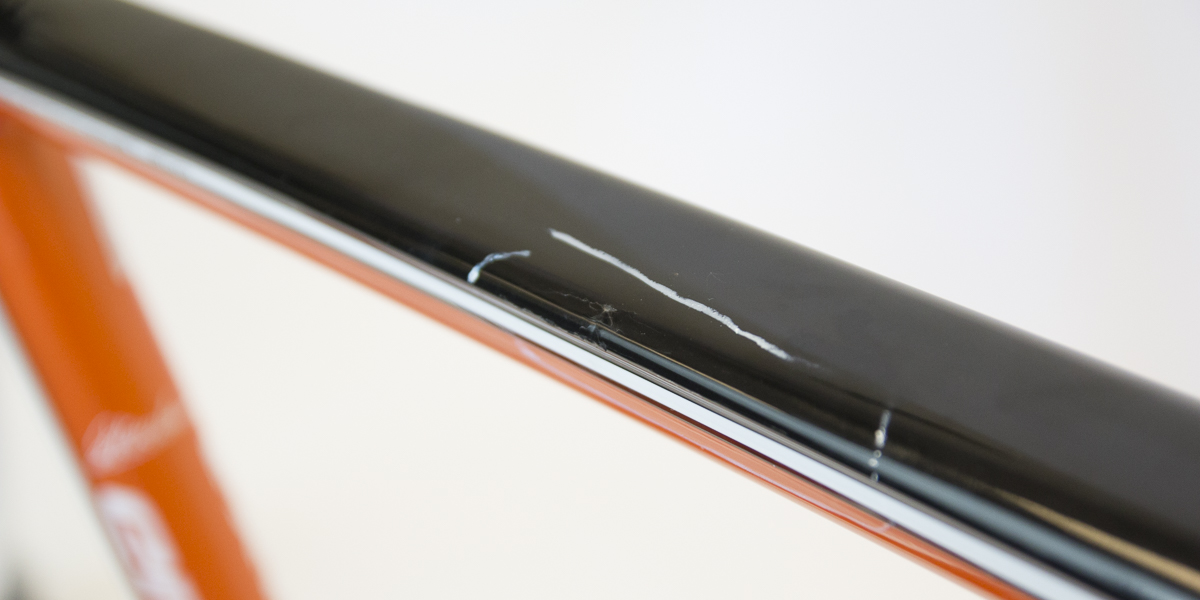

As you can see, the photos depict a small-ish crack running perpendicular to the toptube but our ultrasound scan revealed a massively damaged zone about 4×7″ radiating around the area. Most often, visual inspections leave details unseen, so we scan damages to discover everything we can about the damage and how we can fix it.

The first and arguably one of the most important steps is the removal of any damaged fibers. We custom designed some booths where we are able to wet sand away all the damage, this way cracks cannot further propagate under the repaired area. As you see, a less than one-inch crack requires much material to be removed for a safe and complete repair.

Another reason we ultrasound scan damaged areas is to discover both the actual number of plies used and their original layup orientation. This process allows us to closely mimic the way the frame was created at the factory, it allows us to use fewer materials and eventually turn repair much more quickly.

The next step is the layup. Using the data gathered in the inspection process, we take our prepreg carbon fiber and recreate the layup schedule and perform the repair ply by ply. After cutting the pieces of prepreg, we gently apply them and continually debulk the repair as we add more layers. This ensures solid, voidless compaction for a safe and robust repair.

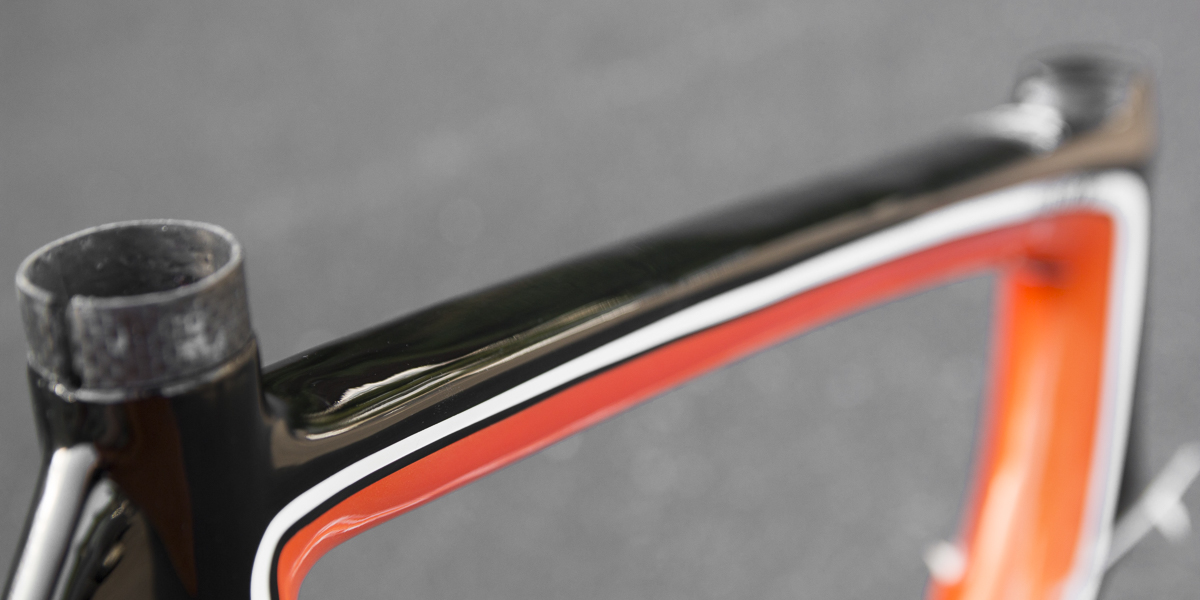

Our final finishing steps are what truly bring life to the repaired area. Our painter is incredibly talented at matching original paint colors and he loves hiding our repairs under an amazing final paint coat.

Accidents happen to even the most robust of frames, and that’s why we’re here. We think every carbon fiber frame is worth saving and that’s exactly what we’ve been doing for nine years now.